Being tasked with choosing the materials for a playground surface that will experience millions of footsteps (particularly those of children) is harrowing – especially if you don’t have a construction background! If you’re in charge of selecting a flooring surface for a playground – we often talk to daycare directors, early childhood center administrators, church administrators, and city managers, for example – you have a lot of options and information to sift through. So what’s the deal with poured rubber surfacing for playgrounds? Also called “wet pour rubber” or “poured-in-place (PIP) rubber”.

Is Poured-in-Place Rubber the Best Option for Playground Flooring?

Researching playground surfacing means you’re going to learn about poured rubber, also commonly called pour-in-place (PIP) rubber or poured playground surface. For this post, we aim to answer the most important questions you’ll be asking: how does poured rubber measure up against other playground surfacing options in terms of safety, cost, and quality?

- Safety of Poured Rubber for Playgrounds

- Cost of Poured Rubber for Playgrounds

- Quality of Poured Rubber for Playgrounds

- Installation of Poured Rubber for Playgrounds

Safety of Poured Rubber Playground Flooring

When you’re discussing the surface for a playground, of course, the most important consideration is safety. This is where pour-in-place rubber (also called PIP rubber surfacing) can’t be topped.

Pros:

- Poured rubber surfacing is durable, soft, and can’t splinter. The chief complaints from parents and kids about popular playground surfaces like wood chips is that they splinter, and pieces find their way into skin, eyes, shoes, and clothes. Pavement is also likely to crumble as it ages, and doesn’t provide any cushioning from falls.

- This type of surfacing was also specifically designed to be extremely shock-absorbent. Just 4.5 inches of poured rubber provides a surface on which a child can safely land from a 10-foot fall, according to American Standard Testing Methods (ASTM), the institution that sets industry safety standards.

- Parents and playground administrators don’t have to worry about chemical sensitivities. adventureTURF uses only premium rubber made from natural materials, EPDM rubber (which helps the surface resist cracks due to severe temperatures and weather), and SBR rubber (which helps the surface stay flat and supple). These materials are free of metal, wood, harsh chemicals, and other compounds that may irritate sensitive skin, aggravate allergies, or cause other health issues.

- On playgrounds near areas where animals may roam, poured rubber provides peace of mind that kids won’t encounter any “surprises” that are sometimes found buried in mulch playgrounds. The same goes for any potentially harmful items humans may have left behind (they won’t be buried in the material).

-

Poured rubber playgrounds are wheelchair accessible and safe for those with physical disabilities. Poured rubber playground flooring is ADA-compliant, meaning it’s wheelchair accessible and safe for those with physical disabilities. Childcare experts agree that youngsters with special needs (and their non-disabled peers!) greatly benefit from inclusive playgrounds, and pour-in-place rubber is widely viewed as the best surfacing option to allow safe and easy play among those with physical limitations.

Cons:

- Depending on the climate of your location (this applies particularly to dry, cold climates), PIP rubber can become hard over time. This is why experts recommend administrators check in every few years to see if the playground should be topped off with a fresh layer of rubber, which is a simple and fast process.

Cost of Poured Rubber Playground Surfacing

Pros:

- One of the strongest cost-saving factors in poured rubber’s favor is the lack of yearly maintenance to be figured into your budget. A pour-in-place playground surface will generally last about 10 years (depending on foot traffic) before any type of upkeep is required — no need to truck in new surface filler every spring. With proper maintenance, it can last as long as 12-15 years.

- After that, maintenance is simple. The surface can be treated with a coating to renew its wear and weather resistance, and on high-traffic playgrounds, new top layers can be poured onto the existing surface.

- Spot-repairs can be made. Note that not every poured rubber playground requires an entirely new playground surface. Often a playground can be completely revitalized by simply adding a new color cap or wear layer to the surface. This restoration technique will actually improve the playground’s safety rating and is a budget-saver.

- Using this type of surface also makes your playground eligible for LEED® credits and state grants, to help defray your up-front cost.

- Learn more about the cost of poured rubber playground flooring here.

Cons:

- The initial investment to cover a playground with PIP rubber is not the cheapest available option. However, the longevity of the material and its minimal maintenance costs render it comparatively low-cost in the long run.

Quality of Poured Rubber Playground Surfaces

Pros:

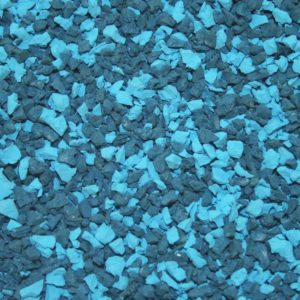

- The granules that make up poured rubber playground flooring provide the opportunity to cost-effectively customize the appearance of your playground. You can select the depth, color, shape, and design of the surface – meaning school colors, logos, and even games can be permanently incorporated.

- We often hear that poured rubber surfacing makes it easier to maintain a playground that appears clean and welcoming. The surface is smooth and easy to clean, and unlike mulch or stone, it won’t get kicked out of place by busy feet. The customizable appearance means you’re able to make design selections that allow it to blend into the surrounding area, creating a more natural look than pavement.

Cons:

- As noted above, PIP rubber doesn’t last forever (as does any playground flooring material). You can expect the surface to need more comprehensive resurfacing after about a decade.

Installation of Poured Rubber Playground Flooring

Poured rubber playground surfacing is mixed and hand-troweled on site.

Pros:

- It turns out that this safe and cost-conscious method of playground surfacing is also one of the easiest for professionals to install. Poured-in-place rubber safety surfacing is mixed and hand-troweled on site. You can view videos of adventureTURF’s installation process here.

Cons:

- Installation must be done by a professional who has the right tools and experience.

- Surface prep with a base is needed.

Next Steps

Now that you’ve learned more about the basics of poured rubber surfacing, you’re going to want to compare it to other options and dive into the details. You can read more about rubber playground flooring from adventureTURF and find some FAQs we answered. We’ve also created a gallery where you can browse some of the awesome playground designs we’ve completed across the country.

You probably still have questions – you can contact us for answers. And if you’re ready to take the next steps, reach out to us to request a free quote. We’d love to help you create a place for adventure!

With so many different qualities and characteristics to consider, choosing a playground surface can be bewildering. That’s why we’ve created an ultimate guide to all the pros and cons of 11 of the most popular playground surfaces, from wood chips to recycled rubber mulch.

![]() We install poured rubber flooring for playgrounds in the entire USA. Contact us for more information or get a free quote.

We install poured rubber flooring for playgrounds in the entire USA. Contact us for more information or get a free quote.

FAQs About Poured in Place Playground Surfacing

Poured rubber is playground flooring that’s seamless and contains very small rubber granules that are stuck together. It’s not a loose material (like rubber mulch, wood chips, sand, or dirt). It’s a “solid” rubber surface for playgrounds or unitary playground surface, meaning that it’s not made up of rubber tiles.

Poured-in-place rubber is also called poured rubber, wet pour rubber, pour-in-place rubber (PIP), rubber playground turf, bonded rubber stone, or a playground foam surface. There’s both pros and cons of using it for playgrounds, as with any playground surface.

Poured rubber is a very durable playground surface. Its longevity really depends on factors such as:

- How well it was installed

- Quality of material used

- How much the playground is used

- Weather/climate

As with any playground surface, regardless of how well it was installed, poured rubber for playgrounds does eventually wear out. You can expect it to need more comprehensive resurfacing after about a decade.

For larger “commercial” playgrounds (for parks, schools, water parks, etc), it’s typically best to leave it to those who have the right tools and experience needed to make sure it’s installed properly. As mentioned previously, if it’s not, or the quality of the material used is sub-par, you’re going to have to replace the surface much sooner. That said, you should be careful when choosing a poured rubber playground installation company.

It’s installed by mixing the materials in a very specific way (using specific tools), poured, and then hand-troweled into place.

Yes, it’s ADA-compliant, wheelchair accessible, and one of the easiest playground surface types for those with disabilities to navigate. Accessible/inclusive playgrounds, and pour-in-place rubber is widely viewed as the best surfacing option to allow safe and easy play among those with physical limitations.

Learn more about the safety of poured rubber playground surfacing.